There are two main types of riveted joint: lap-joints and butt-joints(Fig.4). The rivet is driven into the target materials with high force, piercing the top sheets and spreading outwards into the bottom sheet of material under the influence of an upsetting die to form the joint.įactors in the design and specification of rivets include the size, type and material for the rivet, the type of joint, and the spacing between rivets. An example of the application of a closed end blind rivetĪ further type of rivet with potentially many over-all advantages, from the production perspective, is the self-piercing rivet that does not require a predrilled hole.

The advantage of blind rivets (Fig.3) is that they require access to only one side of the joint.įig 3. The two main types of rivet are tubular and blind and each type are available in amultitude of varieties. In general a given size rivet will be not as strong as the equivalent threaded fastener. Care needs to be taken in the selection of material and coating to avoid the possibility of corrosion by galvanic action. A variety of coatings are available to improve corrosion resistance. Rivets can be made from any ductile material such as carbon steel, aluminium and brass. Two historical examples of the use of rivets on the Lockheed Electra and RB211engine nacelle.

#RIVET BOLT CONNECTIONS INSTALL#

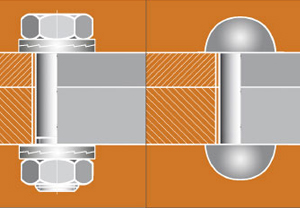

Rivets tend to be much cheaper to install than bolts and the process can be readily automated with single riveting machines capable of installing thousands of rivets an hour.įig 2. see Fig.2) boilers, ships and boxes and other enclosures. Rivets are widely used to join components in aircraft (e.g. 1.įig.1 Conventional rivet before and after setting

#RIVET BOLT CONNECTIONS FREE#

They consist of a preformed head and shank, which is inserted into the material tobe joined and the second head that enables the rivet to function as a fastener is formedon the free end by a variety of means known as setting.Ī conventional rivet before and after setting is illustrated in Fig. Some rivets will even break off during installation.Rivets are non threaded fasteners that are usually manufactured from steel or aluminium. Rivets are permanent fasteners, so you can’t easily remove them. You can easily remove bolts after installing them you just need to use the same bit that you used to install the bolts but in reverse. Blind rivets, for example, typically require a special tool to install.īolts are temporary fasteners, whereas rivets are permanent fasteners. Rivets, on the other hand, may require a special tool.

#RIVET BOLT CONNECTIONS DRIVER#

You can install bolts using a traditional driver with the appropriate bit. You can install rivets by inserting the smooth shank into a hole.Īnother difference between the bolts and rivets involves their installation. They still have a shank, but there’s no threading on the shank. The bolt’s threading will catch with the hole’s threading. You can install a bolt by driving it into a threaded hole. Bolts are designed for use inside threaded holes. While they are both used to join two or more components, bolts and rivets aren’t the same.

Blind rivets, conversely, are designed for fastening applications where you can’t access the back of a workpiece. Solid rivets consist of a solid shank and a head. Rivets can hold multiple components together, including aerospace components. They are used to hold components together. Like with bolts, they typically have a head at the top. Rivets are fasteners consisting of an unthreaded shank. If a bolt has a hexagonal head without a recess, you can use a hex socket bit to install it What Are Rivets? To install a bolt, you’ll need to use a bit that accommodates the bolt’s head. All bolts have a shank, which is either partially or fully threaded depending on the bolt type.Īt the top of a bolt is the head. Rivet: A rivet is made up of round ductile steel bar which. The shank is the main cylindrical body of a bolt. While the connection procedure for riveted connections is same as that of the bolted connections. What are bolts and rivets exactly, and how do they differ? What Are Bolts?īolts are fasteners consisting of a threaded shank and a head. Two of the most common types of fasteners used in the construction of airplanes are bolts and rivets. Fasteners are used to hold components together. Commercial jets, for instance, contain an average of 1.5 to 3 million fasteners. Fasteners are an essential part of all airplanes.

0 kommentar(er)

0 kommentar(er)